Contact Person: Eric Wang

Tel: 0730-8688890Phone: 15173020676

E-mail: wangfp@cseco.cn

E-mail: wangfp@cseco.cn

Address: Zhongke Industrial Park, Yueyang Economic & Technological Development Zone, Yueyang, Hunan, China

1. Changing the dynamics conditions during the solidification process (i.e., mechanical model theory);

2. Changing thermodynamics condition during the solidification process of (i.e., thermal model theory);

3. Improving material migration conditions during the solidification process (to make the components uniform).

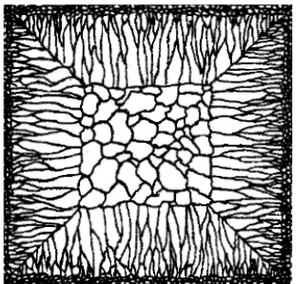

The strong electromagnetic stirring force enable the un-solidified molten steel flush the end of the solidification, cut off and corrode the crystal arm of columnar crystal, forming a large number of dendrite fragments as crystal nucleus of equiaxed grain, making the grain multiplied grown, so as to inhibit the growth of dendrites.

The electromagnetic stirrers are used in the continuous casting process to improve steel quality and to increase the steel production. According to the position along the casting strand and metallurgical effects, stirrers can be classified mold, strand and final stirrers.

The benefits obtained using one or more EMS in combination include surface and sub-surface quality, internal and central soundness.

| EMS type & combination | M-EMS | M+F-EMS | M+S+F-EMS | M+S-EMS | S-EMS | S+F-EMS |

| Pinhole & blowhole | *** | *** | *** | *** | — | — |

| Surface & subsurface cracks | *** | *** | *** | *** | — | — |

| Break-out reduction | *** | *** | *** | *** | *+ | *+ |

| Solidification structure & internal crack | ** | ** | *** | *** | ** | ** |

| Centerline segregation, center porosity | ** | *** | *** | ** | ** | ** |

| V segregation | — | *** | ** | * | *+ | ** |

Keywords: roller electromagnetic stirring (IN-ROLL EMS); Fe–17 wt% Cr–0.6 wt% Ni steel; solidification structure; number of pairs for rollers; washing effectAbstract: We present a segmented coupling model for slab casting by roller electromagnetic stirring (In-roll EMS) of electromagnetic, flow, hea

View More

The mechanism of electromagnetic stirring for continuous casting is to strengthen the movement of residual molten steel in the strand by means of the electromagnetic force generated by the electromagnetic stirrer, which can change the flow, heat transfer and material migration process during

View More

Study on the In-mold Flow Behavior Driven by a Subsurface Electromagnetic Stirring for IF Steel Slab Casting Abstract: A three-dimensional numerical model coupling the electromagnetic field, fluid flow and level fluctuation has been developed to investigate the flow behavior of molten steel in a sla

View More